The MPS type offers:

A growing demand for clean air requires constant further development of our minipleat systems. From standard to special solutions, we can realize everything for you. Cooperation with products from market leaders guarantees a competitive solution for you.

Processing hot-melt foam and simple parameter determination are just two of the milestones we have achieved for you in the past.

Progressive and customer-oriented

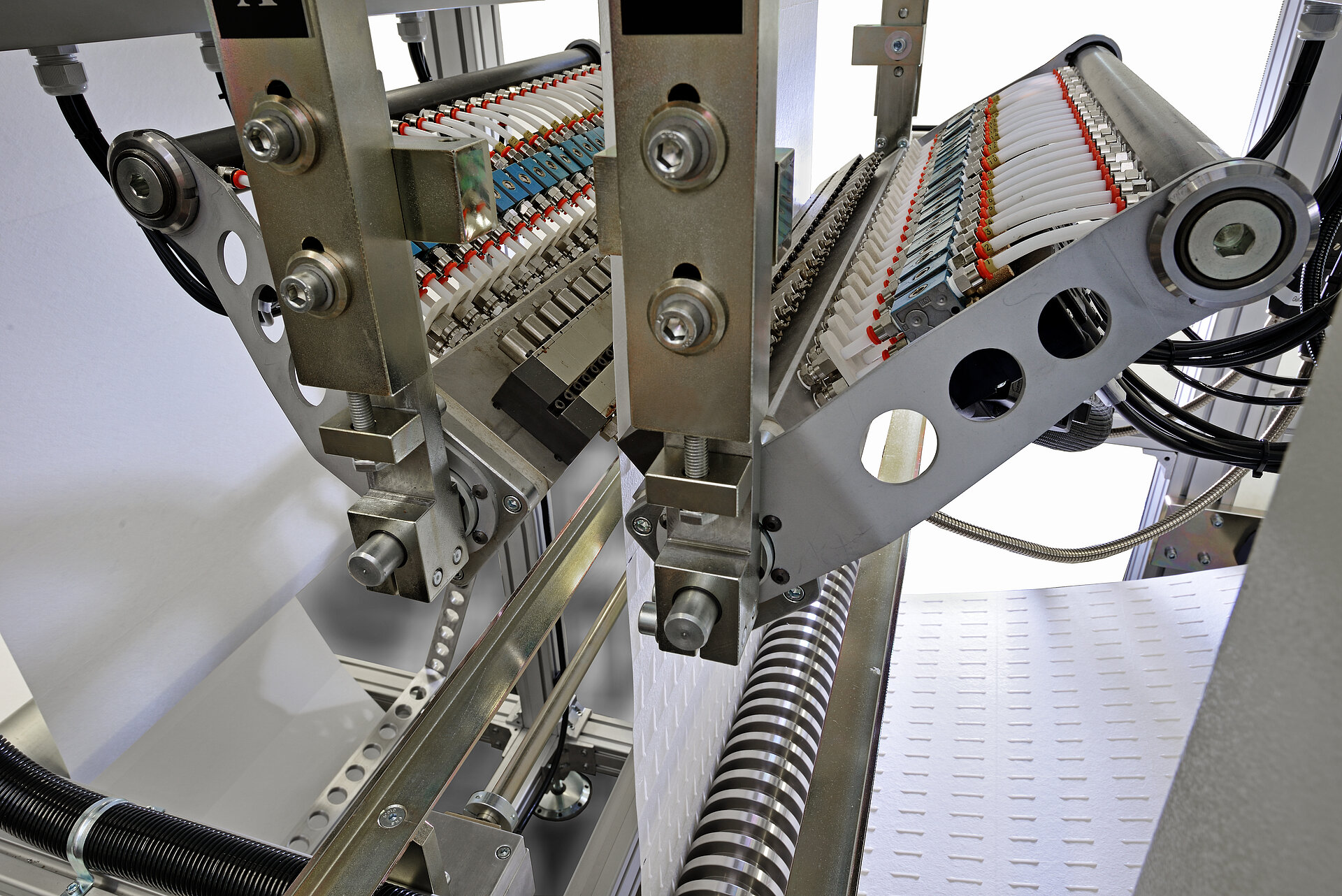

Our minipleat system offers maximum versatility and performance, whether used as an integrated system module in a line or as a stand-alone solution. The flexibility of this system is therefore already evident in its placement options, as it can also be easily positioned behind any folding machine. Thanks to its freely programmable nozzle control, it can also be adapted to a wide variety of requirements. The application is extremely user-friendly and can be individually configured. Optionally, the Smart pleat pack designer program is available, which significantly simplifies parameter finding.