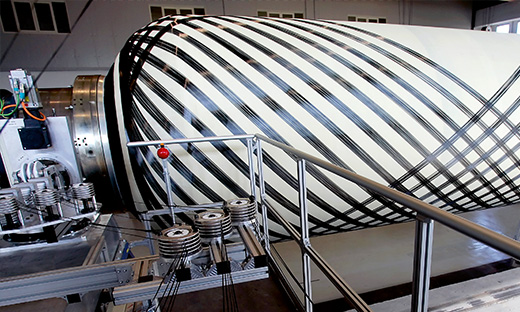

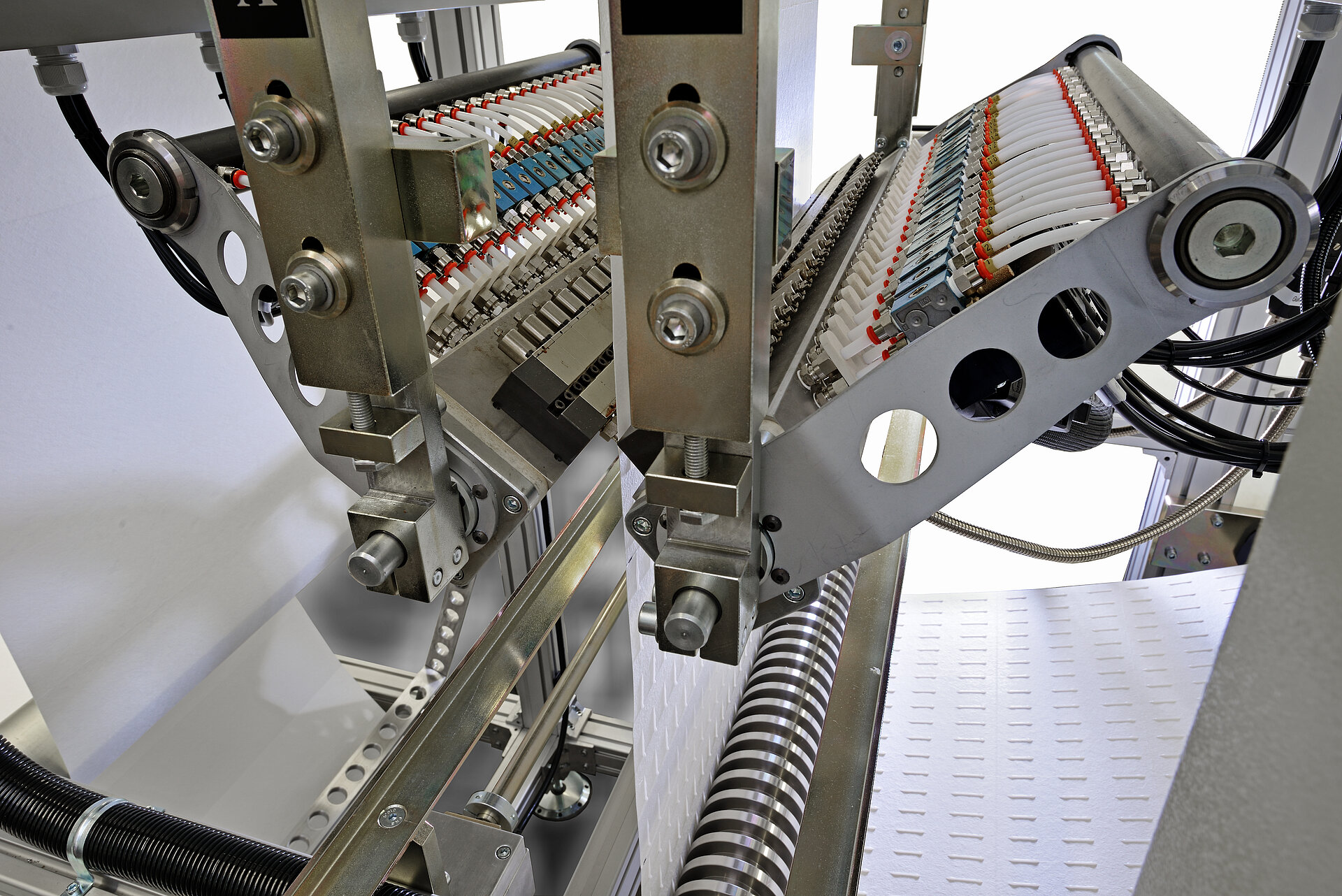

The cooperative orientation, in-depth industry knowledge, and experience amassed over decades in solving demanding tasks form the foundation of the trust that customers have been placing in Roth Composite Machinery for many years.

The machinery experts' know-how lies in their ability to listen, think analytically, and develop customer-specific overall solutions with new technologies from there. This process not only builds trust but also satisfaction...

Choosing a machine from Roth Composite Machinery is a decision for the best quality. Should a problem occur, you can rely on the worldwide service of Roth Composite Machinery, and this is completely independent of the location.